Foshan Henwi Technology Co.,Ltd

5L Vaccum Emulsifying Mixer

5L Vaccum Emulsifying Mixer

Couldn't load pickup availability

Multifunctional Laboratory Heating, Homogenizing, Vacuum Emulsifying Mixer

This high-performance laboratory emulsifying mixer combines heating, homogenizing, vacuum processing, lifting, mixing, and emulsifying in one compact system. Ideal for cosmetics, pharmaceuticals, food, and chemical industries, it is specifically designed for R&D and small-scale production, ensuring consistent results, smooth texture, and efficient operation.

🔥 Precision Heating System

Uses electric or steam heating to maintain materials at optimal temperatures, improving emulsification efficiency and fluidity — perfect for temperature-sensitive formulations.

⚡ High-Shear Homogenization

Features a high-speed homogenizing head that creates powerful shear forces to break down particles and ensure uniform blending for a smooth, stable final product.

🌀 Vacuum Deaeration Function

Operates under vacuum conditions to remove air bubbles during mixing, preventing oxidation and ensuring higher product purity and stability.

⬆️ Automatic Lifting Mechanism

Allows easy lifting of the mixing head for effortless cleaning and quick batch changes — ideal for fast-paced lab environments.

🔄 Variable-Speed Mixing

Equipped with a frequency-controlled motor and scraper-style mixer to provide even, thorough mixing — especially effective for high-viscosity materials.

💧 Efficient Emulsification

Creates stable emulsions by combining liquids or liquids with solids using a high-speed rotating emulsifying head — essential for creams, gels, lotions, and other semi-solid products.

🧪 Compact, Multi-Purpose Design

Small footprint, multifunctional operation, and user-friendly controls make it perfect for new product development, pilot production, and lab use.

✅ Applications Include:

· Cosmetic creams, serums, and masks

· Pharmaceutical sample production

· Food pastes, flavor blends, and gels

· Chemical emulsions and dispersions

Parameter

| Model: HWVM-LB-5L |

| Working capacity: 5 Liters |

| Viscosity: Max. 100,000cp |

| Heating method: electric (Water bath) |

| Mixing type: Upper frame oar scraper mixer |

| Mixing motor power: 220W |

| Mixing speed: 0-200rpm |

| Homogenizer type: Top homogenizer |

| Homogenizer power: 750W, Germany motor |

| Homogenizer speed: 8000-30000rpm |

| Vacuum system: 150W |

| Control method: Button control |

| Jacket: Double jacket,3 layers |

| Tank's materials: 5mm,Glass |

| Water bath: 1000W |

| ① Electric lifting system | ⑦ Homogenizer(8000-30000rpm) |

| ② Frame wall scraper mixing (65rpm) | ⑧ Multifunctional lid |

| ③ Tank with jackets heating | ⑨ 180°Tilting Discharge |

| ④ Discharge | ⑩ Water bath |

| ⑤ Control Panel | |

| ⑥ Vacuum pump |

Stirring & Homogenizing: Dual Core Mixing Technology

The mixing and homogenizing systems are at the heart of this laboratory vacuum emulsifying mixer, delivering precise emulsification, blending, and dispersion for a wide range of formulations. Here's how each function supports your lab processes:

1. Mixing Function (0–200 RPM)

Ideal for handling various viscosities, the stirring module ensures even distribution of all ingredients.

· Low-Speed Mixing: Perfect for gently blending high-viscosity or coarse-particle materials without introducing excess air.

· Wall Scraping Design: Equipped with a scraper (typically PTFE or silicone) to prevent materials from sticking to the container wall — ensuring uniform blending and eliminating dead zones.

· Adjustable Speed Control: Variable frequency drive allows fine-tuned speed adjustment from 0–200 RPM for maximum flexibility based on material type and process stage.

2. Homogenizing Function (8000–30,000 RPM)

This high-speed rotor-stator system creates intense shear forces, essential for micro- and nano-emulsification.

· High Shear Output: Refines particles down to micron or submicron size for stable emulsions and suspensions.

· Vacuum-Compatible Processing: Prevents air entrapment, oxidation, and foaming for cleaner, more stable formulations.

· Fast & Fine Dispersion: Effectively disperses oil and water phases, powders, or insoluble particles into a smooth, uniform product.

💡 Mixing and homogenizing can be used sequentially or simultaneously, making this system ideal for complex emulsions, suspensions, creams, and gels.

Multifunctional Lid

Integrates multiple interfaces for vacuum, heating, dosing, observation, and homogenization.

· Vacuum Gauge: Monitors internal vacuum in real time to ensure air-free mixing.

· Thermometer Port: Enables accurate temperature monitoring during processing.

· Fragrance Funnel: With a sealing valve for precise, contamination-free additive dosing.

· Homogenizer Inlet: Connects to the high-shear head for efficient emulsification.

· Spare Port: Flexible interface for sensors, dosing lines, or condensers as needed.

Electric Lifting System

Enables smooth height adjustment for easier operation, cleaning, and discharging.

· Motorized Control: Adjusts emulsifier head and container height via control panel.

· Lifting Range: 300–500mm stroke fits various vessel sizes.

· Easy Discharge: Lifting allows the main pot to tilt for material pouring.

· Convenient Cleaning: Facilitates removal and washing of the glass tank.

· Smooth & Stable: Designed to lift without impact or vibration.

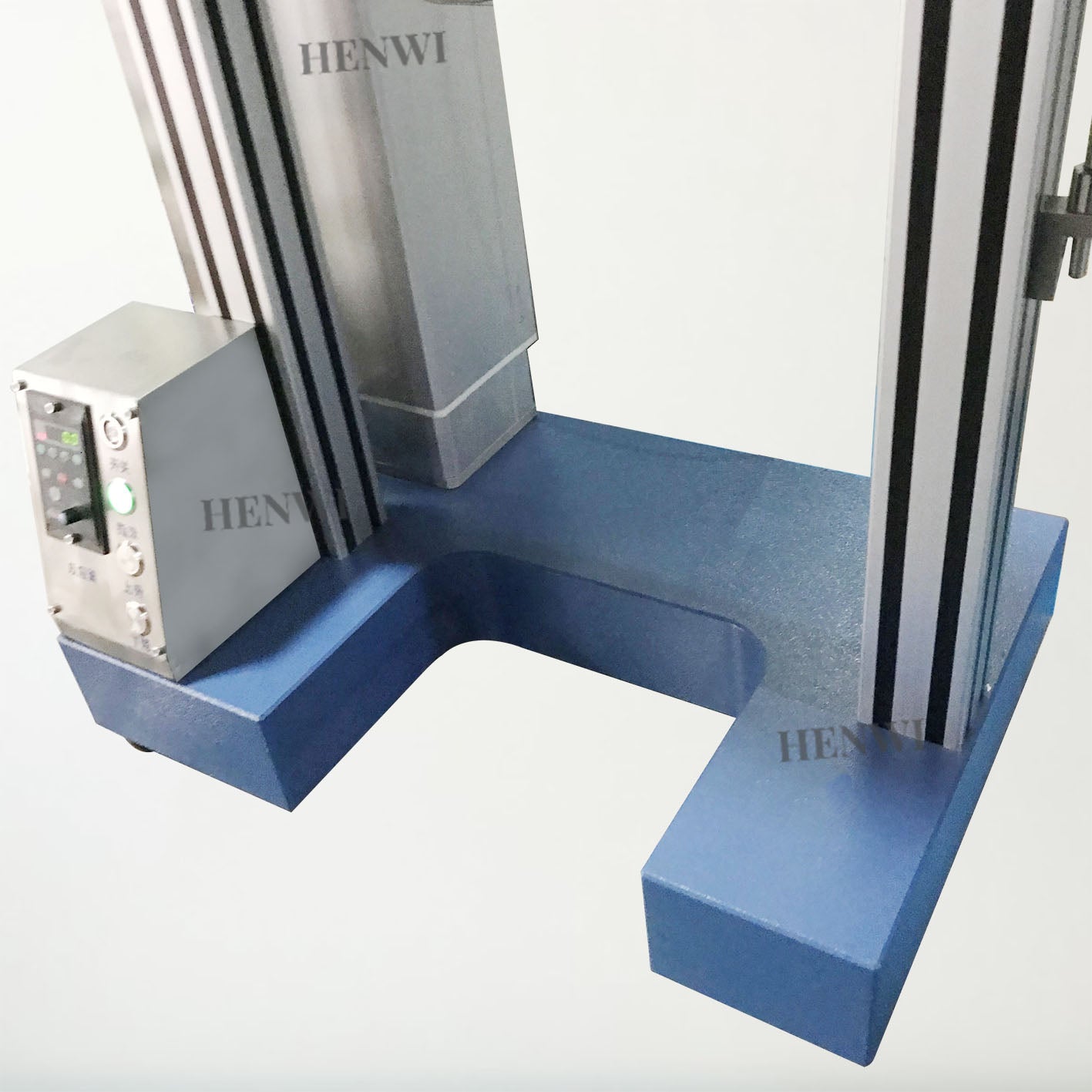

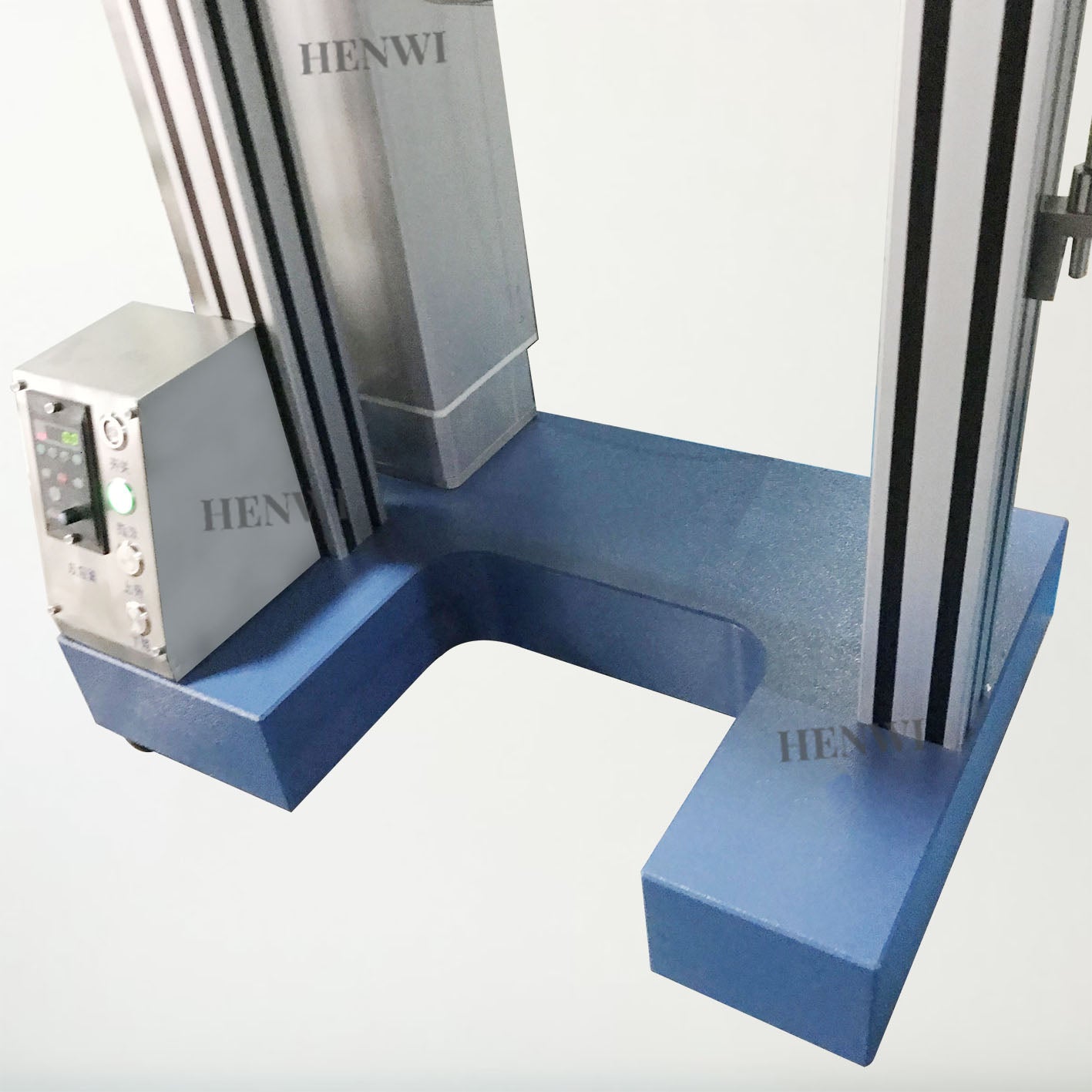

Stable Base

Provides a solid, secure foundation for high-speed and vacuum operation.

· Heavy-Duty Build: Made of high-strength, corrosion-resistant steel for lab use.

· Shockproof Design: Anti-slip pads or vibration dampers reduce movement and noise.

· Compact & Clean: Space-efficient layout with a neat, modern appearance.

· Reliable at High Speed: Maintains stability during high-speed (up to 30,000 rpm) or vacuum conditions.

· Safety-Oriented: Prevents tilting, leakage, or spillage during critical processes.

Vacuum Pump

Creates a stable low-pressure environment for efficient emulsification.

· Oil-Sealed System: Ensures effective gas and moisture extraction.

· Fast Vacuuming: High pumping speed for quick vacuum generation.

· Quiet & Low Vibration: Suitable for quiet, precise lab environments.

· Durable: Lubricated design reduces wear, enabling long-term continuous use.

Constant Temperature Water Bath

Maintains precise sample temperature throughout the process.

· Accurate Control: Digital or analog interface for precise, stable temperature settings.

· Even Heating: Ensures uniform temperature distribution for consistent emulsification.

· Built-in Safety: Overheat protection and low water level alarm for safe operation.

· User-Friendly: Simple controls with clear temperature display.

· Easy Maintenance: Smooth interior surface for quick cleaning and water change.

Why Choose This Mixer?

✔️ Lab-grade precision

✔️ Easy to operate and clean

✔️ High efficiency in small-batch production

✔️ Versatile for a wide range of formulations

Engineered for innovation — empower your lab with this all-in-one emulsifying solution.

Share