Foshan Henwi Technology Co.,Ltd

200L Movable Liquid Heating Homogenizing Mixer

200L Movable Liquid Heating Homogenizing Mixer

Couldn't load pickup availability

Homogenizing mixer machine has high-speed disperser, mixing and disperse viscously, solid and liquid, etc. various kind of raw material will be dissolved which is such as AES, AESA LSA, during liquid production which can save energy consumption and shorten production the and shorten production period. To produce liquid washing products, like shampoo, liquid soap, bath shower, dishwashing, hand washing, etc.

Application

Parameter

| Model: HWHM-MT-200L |

| Working capacity: 200 Liters |

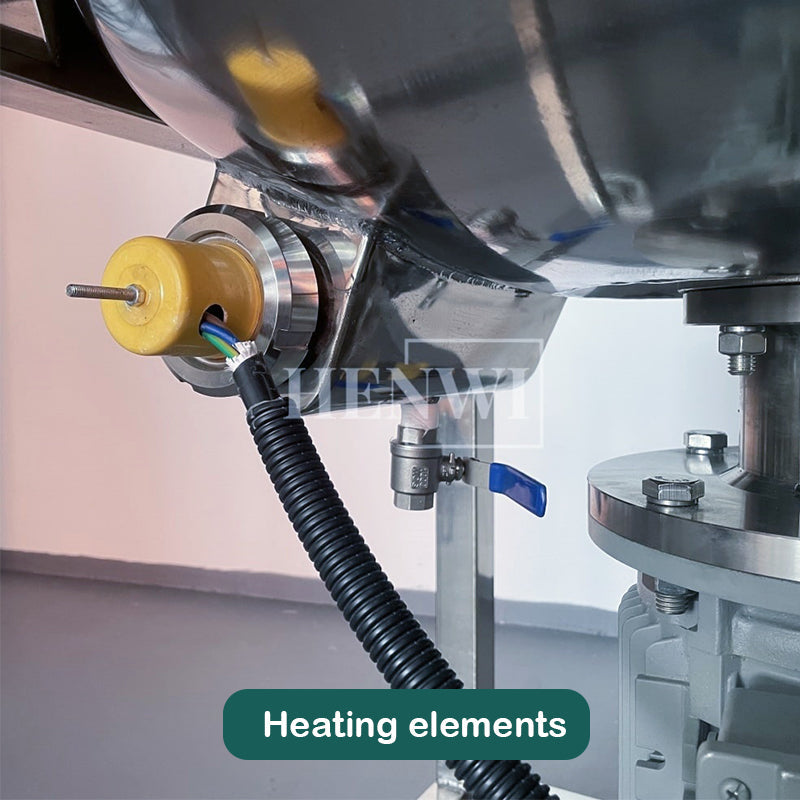

| Heating method: Electric 27KW |

| Mixing type: Upper frame oar scraper mixer |

| Mixing motor power: 2.2KW, Siemens motor |

| Mixing frequency inverter: 2.2KW |

| Mixing speed: 0-65rpm |

| Homogenizer type: Bottom homogenizer |

| Homogenizer power: 4KW, Siemens motor |

| Homogenizer frequency inverter: 4KW |

| Homogenizer speed: 0-3000rpm(50Hz)/0-3600rpm(60Hz) |

| Control method: Button control |

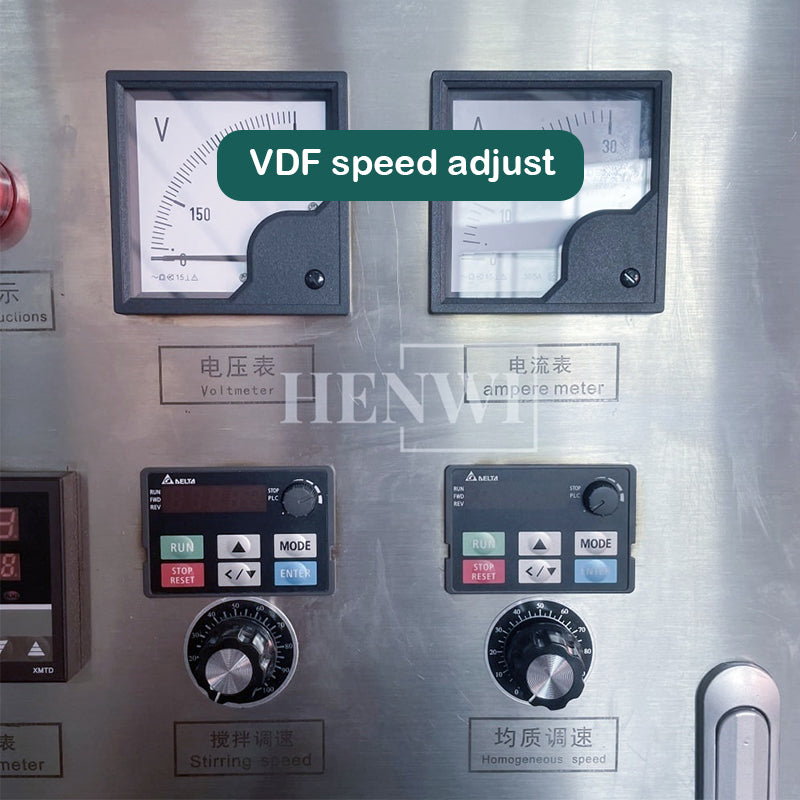

| Frequency inverter: Delta |

| Electrical components: Delixi |

| Jacket: Double jacket,3 layers |

| Tank's materials: Inner layer 4mm/SUS316, Middle layer 3mm/SUS304, Outer layer 2mm/SUS304 |

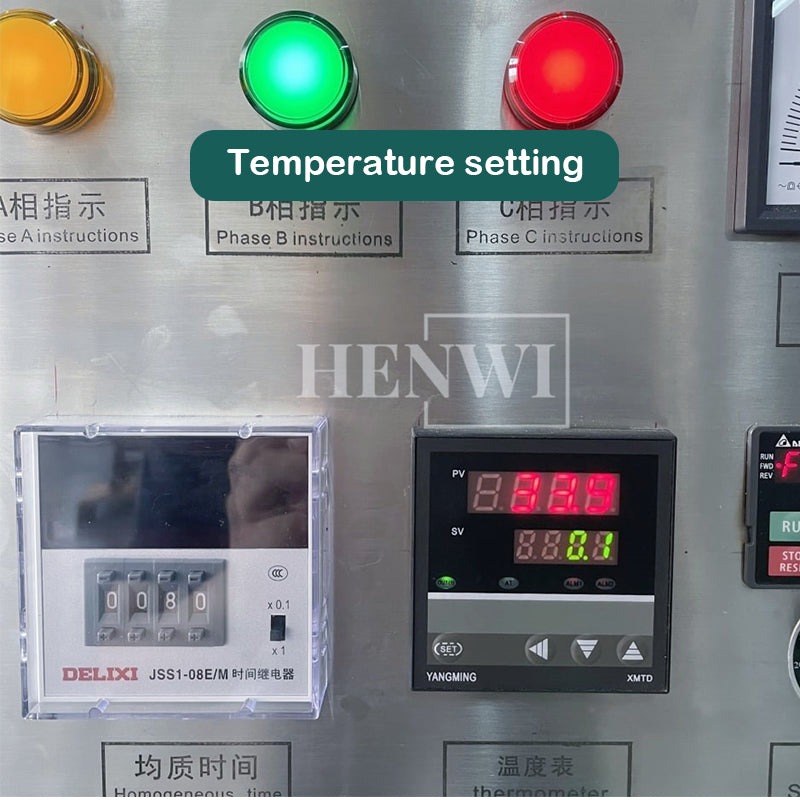

Control Panel |

|

Simple and clear operation buttons, with notes in English or customized language required by customers. Contains voltage, current, functions switch, working indicator light, timer, speed regulator and emergency stop. |

Frame Scraper Mixing |

|

The frame-type scraper mixer can effectively mix the materials stuck on the wall. The powerful motor can mix the materials up and down. It is equipped with a frequency converter and a reducer. The stirring speed can be adjusted from 0 to 65 rpm. |

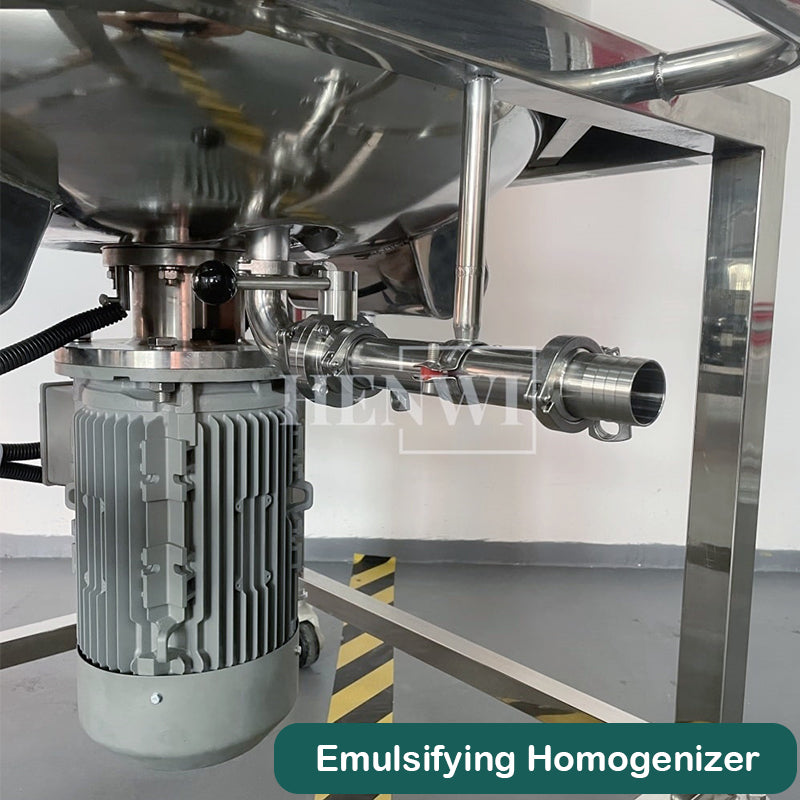

Emulsifying Homogenizer |

|

The high shear speed of 3000 rpm makes the material fully emulsified in the gap between the stator and the rotor, so that the oil phase and the water phase are fully mixed, and the Emulsifying Fineness <0.2um is obtained to obtain a stable emulsion. |

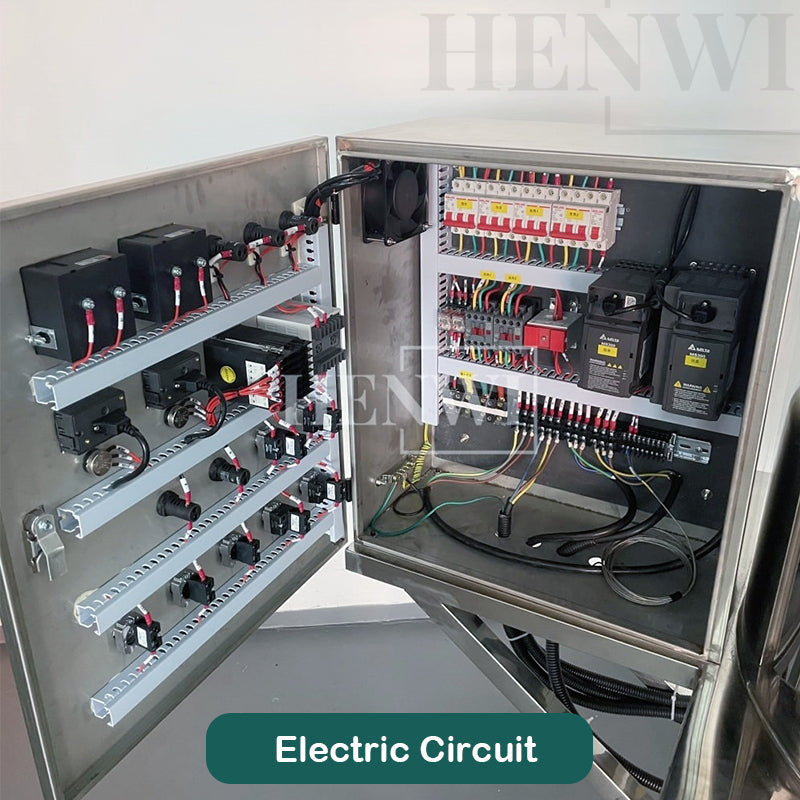

Electrical box |

|

Neat wiring helps reduce issues such as interference, crossovers, and short circuits between wires, improving the reliability and stability of the machine, and reducing the risk of circuit failures and safety incidents. It facilitates maintenance personnel in identifying and locating faults, enabling quick repairs and replacements. |

Foldable lid |

| Foldable lid for easy feeding and cleaning |

Share